- Dynamica Ropes

- Dyneema® ropes

HMPE/Dyneema® ropes stronger than steel wire

Many users ask “What is HMPE/Dyneema® and Dyneema rope”? The short answer is that Dyneema® is the strongest man-made fibre™ in the world.

Dyneema® offers exceptional strength-to-weight ratio, being up to 15 times stronger than steel by weight, while also being lightweight, durable, and resistant to humid conditions, chemicals, and UV rays.

Dyneema® is also called ultra-high molecular weight polyethylene (UHMWPE), used for manufacturing several types of ropes, slings and tethers. Its many benefits make Dyneema® ropes ideal for demanding applications such as marine, industrial, and outdoor uses where high performance and reliability are required.

You can find our high-quality Dyneema® products in industries such as heavy lifting, on- & offshore wind, FOWT, oil & gas, maritime, subsea, defence, winch, vehicle recovery 4x4, aquaculture & fishing and a few more. At Dynamica Ropes, we manufacture our rope solutions with HMPE/Dyneema® in order to offer you the lightest, strongest and most reliable solution possible.

In fact, our rope solutions have such high strength performance, that they are replacing steel wire and chains for heavy lifting operations both on- and offshore.

Our HMPE/Dyneema® product range

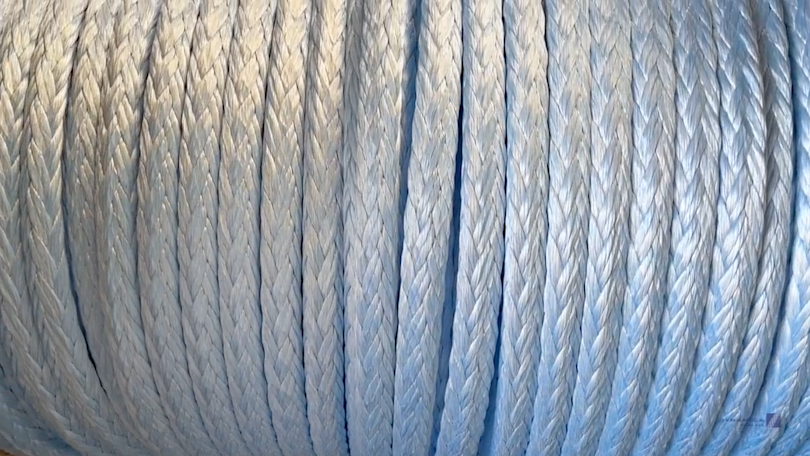

At Dynamica Ropes, all of our products are constructed as 12-strand braid or parallel fibres, but they vary in construction, cores and covers. Below you can see our standard products:

| SecureLift Slings | Fibre round slings |

| SafeLift Slings | Dyneema/HMPE rope slings |

| Tethers | Subsea/Deepsea fibre & rope Tethers |

| Mooring & Towing ropes | Abrasion - & UV resistant ropes |

| Winch ropes | Winch ropes for 4x4, gliders, lashings, taglines, helicopters & j-tube |

| Ropes | A variety of ropes made with the worlds strongest man-made fibre |

For most applications, we produce the products with HMPE/Dyneema® fibres SK75 and SK78. On request, we produce ropes with SK99, DM20 fibres and with XBO treatment.

SK75 and SK78 outperform all the other HMPE fibres in measured strength, ensuring a stable performance in your rope. Moreover, the creep lifetime under equal load and

temperature is much longer. SK78 has lower creep than SK75, making it the preferred choice for static applications.

Production of Dyneema® Ropes

Come backstage to the Dynamica Ropes production department and see how we produce the strongest ropes, slings and tether solutions to match your needs and expectations.

The correct Dyneema® Rope solution is value for money

When choosing your rope solution, sling or tether, it is important to consider:

Material: SK75, SK 78, SK99, DM20, HMPE

Construction: 12-braid, core

Cover material: 12-braid, 24-braid, 32-braid

Coating: PU, LAGO, XBO, stiffness/flexibility, color

Minimum breaking load (MBL) / working load limit (WLL)

Length / effective working length (EWL)

Termination: Soft eye, thimble eye

At Dynamica Ropes, we assist you in choosing the correct solution for specifically your operation – everything from material to cover.

We offer great know-how whenever you need assistance as our R&D team have several years’ experience in designing and manufacturing rope solutions, lifting slings and tethers made with HMPE/Dyneema®.

Types of synthetic fibres

There are many different synthetic fibres besides HMPE/Dyneema® e.g.:

Aramids (Kevlar)

Vectran

Nylon

Polypropylene

Polyethylene (Dyneema® & Spectra)

HMPE/Dyneema® fibre is superior to the above mentioned fibres in terms of:

Weight basis

Abrasion resistance

Fatigue resistance

Fungal resistance

UV stability

Resistance to chemical substances

Positive Buoyancy

Dyneema® rope do's

When choosing ropes, slings or tethers with HMPE/Dyneema® there are a few important factors to be aware of as this can influence the lifespan of your equipment:

UV resistance

Chemical resistance

Creep

Want to know more about HMPE/Dyneema®? Download the guidelines here:

Dyneema® rope don'ts

When choosing ropes, slings or tethers with HMPE/Dyneema® there are some clear don’ts.

Do not tie knots! Introducing knots to rope will cause up to 60 % loss in strength of the rope. Instead, opt for splices. When executed by trained and authorised riggers, you will only lose about 10 % of the initial strength.

Our riggers have performed thousands of splices. They are educated to handle unique and custom-made products to ensure a uniform and premium manufacturing process.

FAQ about Dyneema Ropes

What is Dyneema, and how is it different from other ropes?

Dyneema is a brand of ultra-high-molecular-weight polyethylene (UHMWPE) known for its exceptional strength-to-weight ratio. It is significantly lighter and stronger than traditional rope materials like nylon and polyester. Additionally, it offers excellent resistance to abrasion, chemicals, and moisture.

How strong are Dyneema ropes compared to other materials?

Dyneema ropes have up to 10 times the strength of steel on a weight-for-weight basis and are significantly stronger than nylon or polyester ropes. This makes them ideal for demanding applications where high strength is required.

What are the main applications for Dyneema ropes?

Dyneema ropes are used in a variety of applications, including sailing,rigging,mooring , commercial fishing (nets and ropes), industrial lifting, offshore energy (towlines, moorings and slings), and even recreational sports like climbing and paragliding.

Is Dyneema rope UV-resistant?

Yes, Dyneema rope is highly UV-resistant and can endure long-term exposure to sunlight without significant degradation, making it ideal for outdoor and marine use.

Is Dyneema rope waterproof or resistant to water absorption?

Dyneema is waterproof and has a negligible water absorption rate. It retains its strength even when wet, making it perfect for marine and outdoor environments, also in very cold weather conditions.

Is Dyneema rope heat-resistant?

While Dyneema has good thermal stability at moderate temperatures, it has a relatively low melting point (about 135°C or 275°F). Prolonged exposure to high temperatures or friction can weaken it, so caution is needed in high-heat applications.

Can Dyneema rope float on water?

Yes, Dyneema ropes are buoyant and float on water, a feature that adds to their suitability for marine and aquatic applications. The specific gravity of Dyneema® is 0,97.

How durable is Dyneema in harsh conditions?

Dyneema performs exceptionally well in harsh environments. It resists saltwater corrosion, extreme cold, and abrasive conditions, maintaining its strength and flexibility even in demanding settings.

Can Dyneema rope be spliced?

Yes, Dyneema ropes can be spliced effectively. Splicing is the preferred method of joining or terminating Dyneema because it maintains most of the rope's strength compared to knots.

How does Dyneema rope perform under load and dynamic stress?

Dyneema ropes have very low elongation (app than 3,5% at break), making them highly efficient under static and dynamic loads. They are ideal for applications requiring minimal stretch and high load capacity.

How does Dyneema compare in weight to other ropes?

Dyneema ropes are incredibly lightweight—7 to 10 times lighter than steel ropes of equivalent strength. This makes them a preferred choice in applications where reducing weight is critical.

What is the expected lifespan of Dyneema rope?

The lifespan of Dyneema ropes depends on the application and exposure to environmental factors, but they typically last much longer than ropes made from other materials due to their resistance to wear and environmental degradation.

How do you properly maintain and care for Dyneema rope?

To maintain Dyneema ropes, clean them with fresh water after exposure to saltwater or dirt, store them in a dry, shaded area, and avoid prolonged exposure to high heat or sharp edges that could cause cuts.

What is the cost of Dyneema rope compared to other solutions?

Dyneema ropes are more expensive than nylon or polyester ropes. However, their superior strength, durability, and lightweight characteristics often justify the higher cost, especially in professional applications.

What are the limitations of Dyneema rope?

Limitations of Dyneema include its lower resistance to high temperatures and susceptibility to cutting or damage from sharp objects due to its relatively low surface hardness.