- Dynamica Ropes

- Products

- SecureLift Slings

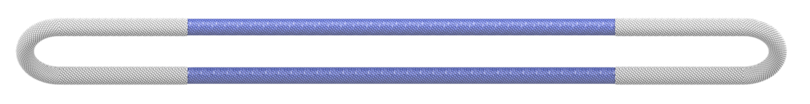

Dynamica SecureLift Slings

Fibre round slings

Technical information

| Construction | Roundsling |

| Core material | HMPE/Dyneema® |

| Body cover | HMPE/Dyneema®, Polyester, Cordura, DuraForce |

| Eye cover material | HMPE/Dyneema®, Polyester, Cordura, DuraForce |

| MBL | 4200 t |

| Length tolerance | +/- 1 % or less |

| Length tolerance, matched pairs | 0.5 % or less |

| Safety | Proof Loaded |

| Safety factor | According to customer specifications |

Need a datasheet?Go to solution request and fill in your details | |

Features

- Strong as steel

- 10 times lighter than steel

- Abrasion resistant

- High cut resistance

- Extremely low length tolerances

- Very low elongation even after multiple lifts

- Quick & easy rigging

Applications

- Lifting

Why choose Dynamica SecureLift Fiber Sling?

The unique feature of Dynamica SecureLift Roundslings is the Proof Load which we provide for each and every sling manufactured at our premises. The Proof Load ensures on the one hand a safe lifting operation, on the other hand that the effective working length (EWL) of the sling is defined even before the first lift, so there is no need for 'training' the sling. It is always done in our Test Bed at our production facility.

All Dynamica SecureLift Slings are made with HMPE/Dyneema® and are manufactured according to DIN EN 1492-2. Every sling is made with safety in focus.

Traditional lifting slings used in many industries (example steel wire or polyester) are for sure strong, but they are also very heavy, difficult to handle and there is always a risk of unforeseen change in the initial EWL after this type of slings have been used few times.

By using SecureLift Fibre Slings, you will obtain cost reductions due to fewer hours spent on checking the rigging accuracy, less lifting equipment needed for the handling of the slings during the rigging process as SecureLift Slings are so light, preventing less back and hand injuries.

Dynamica SecureLift Fiber Slings are a good choice in case of heavy lifting jobs and engineered lifting where length accuracy, easy rigging, abrasion resistance and flexible lifting equipment is required.

Compared with the traditional polyester slings, which absorb water, the SecureLift Fibre Slings do not absorb water and never get heavy or difficult to handle. This means they would not create problems during storage either.

Benefits from Dynamica SecureLift Fiber Slings:

Lightweight

Proof Loaded – safe use guaranteed

Length accuracy – length registered after Proof Load

Exceptionally strong

High resistance against chemicals

High cut and abrasion resistance

When using Dynamica SecureLift Fiber Sling the cost reduction is significant compared with steel wire:

Time saved due to faster handling

Less handling equipment for rigging operation

Less damaged goods

Less injuries due to easy handling

Interested in a Dynamica SecureLift Roundsling? Get more information or a quotation through Solution Request.

Construction

All Dynamica SecureLift Roundslings are manufactured with HMPE/Dyneema® and according to DIN EN 1492-2.

Every Dynamica SecureLift Fiber Sling is custom-made and Proof Loaded with quality and safety in focus.

SecureLift Slings are constructed as roundslings with a variety of options when it comes to covers and protection against abrasion.

Lifting configuration

When you choose to use Dynamica SecureLift Roundslings it is important that you define the application and the configuration, so that you choose the best sling and best protection to handle and control your load. Selecting the correct configuration is as important as choosing your lifting sling.

Any load can be rigged and moved in many ways, therefore, there are a few different types of configurations that will assist you with the requirement.

Straight lift

Straight lift (vertical configuration) is the most common one of all. The crane hook connects the sling at the top and the opposite eye of the sling is connected to the lifted structure. This type of lifting configuration requires protection in the bearing points only.

U-lift

The u-lift configuration distributes the load equally between the two legs of a sling. The legs have to be well protected in case they are not rigged on trunnions but in contact with the cargo like in case of monopole lift. The same goes for the bearing point where the sling is wrapped around the load. When using a basket configuration, the load is supported by the two parts of the sling and then connected to a crane hook.

Proof Loading

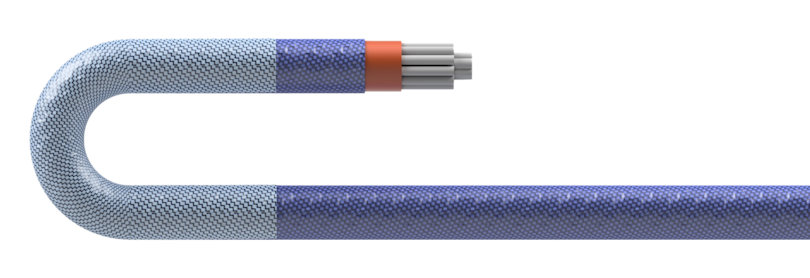

Dynamica fibre roundslings' lead bearing core is constructed of parallel HMPE/Dyneema® fibres protected by several layers of heavy duty fabrics such as Dual Cordura or Dyneema®. The constructional elongation of a sling is caused by the alignment of the fibres under tension. This minimal elongation is removed by Proof Loading in our Test Bed.

We Proof Load all Dynamica SecureLift Slings as they are a safer choice, as the Proof Loading guarantees correct WLL so the sling can carry the load, which it is designed for. We Proof Load up to 500 t in our in-house Test Bed where, on request, a customer representative and 3rd party representative can be present. The Proof Load is done according to DNV-ST-N001. Slings that require higher Proof Load are tested at an external test facility.

What is the benefit of Proof Loading heavy lifting slings?

Choosing a Proof Loaded sling you make a safe choice, as the Proof Loading is our guarantee to you, that the heavy duty lifting sling can carry the load, which it is designed for.

The Proof Loading ensures:

Stable length of the sling

The smallest possible length tolerance in case of multiple lifts

A Proof Loading certificate - part of the documentation

Proof Load example

WLL 100 t

SF 7:1

MBL 700 t

Proof Load to WLL 100 x 1.22 + 20 = 142 t

The Proof Load is significantly higher than the highest load allowed, which the sling can ever be used for during lifting operations.

The precise EWL and length tolerance of Dynamica fibre slings

Dynamica Ropes have an in-house Test Bed equipped with an extensometer that allows measuring the exact elongation of our SecureLift Slings made with HMPE/Dyneema®.

With the know-how based on the empiric testing, we can make very precise EWL calculations on SecureLift Slings. This means that we are able to manufacture fibre slings with a very low EWL (effective working length) tolerance.

The EWL tolerance of our SecureLift Fibre Slings is always according to DIN EN 1492-2.

Since we often deliver our sling solutions for engineered lifting, the EWL tolerance of maximum 1% or even less is often agreed for a specific SecureLift Sling.

All Dynamica SecureLift Slings are Proof Loaded according to DNV-ST-N001 and delivered with a Proof Load Certificate stating the EWL of the rope sling measured under tension.

What is the elongation of Dynamica SecureLift Fiber Sling?

HMPE/Dyneema® fibres have an extremely low elasticity compared with traditional fibres such as polyester and the stiffness is similar to steel wire as the SecureLift Slings are Proof Loaded (trained) in our Test Bed to a value exceeding the WLL.

Constructional elongation

Constructional elongation is the elongation of a loaded fibre sling that results in compacting of the construction and alignment of the fibres and strands in the rope.

We reduce the constructional elongation during manufacturing process as all ropes are subject to the intensive heat-stretching system, which is applied on ropes used for manufacturing of fibre slings.

Later on, the fibre slings are Proof Loaded in our 500 t Test Bed (or at external facilities, if the proof load extends 500 t) and the constructional elongation is removed from the sling.

Elastic elongation

Elastic elongation is a result of the elasticity of the fibres used in the construction of the sling. Each type of synthetic fibre has a different degree of elasticity.

HMPE/Dyneema® fibres have 3-4 % elongation at break. Due to the applied SF (safety factor) and Proof Load, the slings are not elongating when used according to the rules. Dynamica SecureLift Sling elongate by 0.8 % at WLL when used with a SF of 7:1.

How repeatable lifting operations influence on the elongation of Dynamica SecureLift roundslings

One of the functions built into our in-house Test Bed is the programme letting us demonstrate how little elongation our slings have after being used time after time.

To clarify how the EWL of fibre slings changes after several lifting operations, we have Proof Loaded a SecureLift Sling (WLL of 100 t) up to 50 t, 50 times. The average elongation indicates that the elongation is smaller and smaller each time the SecureLift Sling has been loaded.

Need more information? Contact us.

How to cover & protect the SecureLift Roundsling?

SecureLift Slings (according to the DIN EN-1492 regulations for safe use of slings) should be protected on the bearing points as crane hooks, shackles, trunnions and other types of rigging.

Soft slings should be protected from sharp edges, friction and abrasion (DIN EN 1492-1:2000+A1:2008 C.3.6), both from the load side and lifting devices such as crane hooks.

To secure a long lifetime of your SecureLift Slings, it is safe and beneficial to apply a cover to protect the bearing points and to protect the sling body against abrasion in general.

Dynamica Ropes offer different woven cover solutions. See below a short description of woven cover solutions for fibre slings:

Polyester

Single Cordura

Dual Cordura

DuraForce

Dyneema® 1.5 mm

Dyneema® 3.0 mm cover

When choosing the protection for our fibre slings, bear in mind that; HMPE/Dyneema® has a tenacity which is approximately 4 times higher than polyester and nylon. HMPE/Dyneema® also has highly cut resistance and more durable than other synthetic solutions.

The sleeve protection must always be correctly positioned according to the planned lifting operation. For some lifting operations, it may be necessary to supplement this with additional protection.

Dynamica Ropes have experience manufacturing fibre soft slings for a range of different industries, and we are always ready to guide you through our different cover types, in order to find the best solution for your lifting operation.

The correct protection against damages of the sling caused by sharp edges and/or abrasion is part of the standard package from Dynamica Ropes. It can be a part of the sling, or supplied as a complementary product according to the sling design agreed with the customer.

Inspection

Dynamica Ropes offer sling inspection and recertification service and it is our experience that fibre slings, which have been handled and stored correctly, often can be repaired if damaged.

The service agreement includes a professional quality inspection, repair of possible damage, Proof Load in our Test Bed according to the standard and recertification.

Want to know more? Contact us.