- Dynamica Ropes

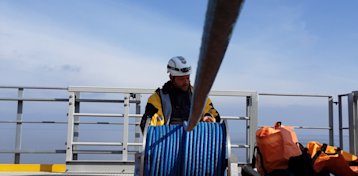

- On- & Offshore Wind

Slings, winch ropes, ropes for On- & Offshore Wind

On- & Offshore Wind Industry consists of many different operations and, therefore, many challenges. However, it all come down to; how to ensure fast yet safe installation?

This question is recurrent as efficient execution is vital to the operation schedule and budget.

Modern technology combined with the skills of engineers, riggers and project managers have made the installation and maintenance of turbines easier. But the ambition for bigger turbines, floating turbines and higher MW makes the above challenge even more prevailing.

Our many years of hands-on experience with engineering and manufacturing equipment for this industry, combined with wind power being part of our Danish heritage means that we can assist you from first idea to final installation regarding the best equipment for your operation.

Read more about our products, services, cases and get to know us better – this way you can choose us as your trusted supplier and partner with ease.

Need help finding what you’re looking for?

Unsure of the best equipment for your operation?

Dynamica SecureLift Fibre Slings

Looking for strong and ultra-light heavy lifting slings for your lifting operation?

Dynamica SafeLift Rope Slings

Looking for a strong and lightweight lifting sling to replace your heavy steel wire?

Dynamica Winch ropes

Looking for recovery ropes, lashings, taglines, gliding ropes, helicopter lines or J-tube lines for your operation?

Dynamica Mooring & Towing ropes

Need strong, lightweight mooring or towing ropes with excellent UV resistance for your operation?

Cases - customised solutions

Read about different projects, we have supplied HMPE/Dyneema® solutions to.

Technical services – we know our fibres!

Engineered HMPE/Dyneema® rope, sling & Tether solutions. Inspection & recertification. Proof Loading & break tests.

Danish manufacturer

Engineering & manufacturing from headquarter in Denmark. Deliver globally – bringing quality solutions to you.

Need help finding what you’re looking for?

Unsure of the best equipment for your operation?

Dynamica SecureLift Fibre Slings

Looking for strong and ultra-light heavy lifting slings for your lifting operation?

Dynamica SafeLift Rope Slings

Looking for a strong and lightweight lifting sling to replace your heavy steel wire?

Dynamica Winch ropes

Looking for recovery ropes, lashings, taglines, gliding ropes, helicopter lines or J-tube lines for your operation?

Dynamica Mooring & Towing ropes

Need strong, lightweight mooring or towing ropes with excellent UV resistance for your operation?

Cases - customised solutions

Read about different projects, we have supplied HMPE/Dyneema® solutions to.

Technical services – we know our fibres!

Engineered HMPE/Dyneema® rope, sling & Tether solutions. Inspection & recertification. Proof Loading & break tests.

Danish manufacturer

Engineering & manufacturing from headquarter in Denmark. Deliver globally – bringing quality solutions to you.

Change the way you work

- for the better

Lighter

Up to 10 times lighter than steel wire, making handling and installation much easier

Strong

Offers the same strength as steel wire but with significantly less weight

Safer

The lightweight solution enables easier rigging and helps prevent injuries

Flexible

We offer design, engineering, customisation & know how for all industries to ensure the perfect rope solution for every application