- Dynamica Ropes

- Products

- Mooring & Towing ropes

Dynamica Mooring & Towing ropes for vessels

Abrasion & UV resistant ropes

Technical information

| Rope material | HMPE/Dyneema® |

| Diameter | Up to 200 mm |

| Breaking strength | Up to 2500 t |

| Construction | 12 strand braided, rotation free |

| Hand friendly | Lightweight, easy to handle |

| Buoyancy | 0.98 |

| UV stability | Very good |

| Creep | Low |

| Chemical resistance | Very good |

| Abrasion resistance | Extremely good |

| Melting point | 144 - 152° C |

| Max. work temp. | 60 - 65° C |

Need a datasheet?Go to solution request and fill in your details | |

High-performance Mooring lines and Towing ropes for demanding marine applications

Made from high-performance Dyneema® fibre, these ropes offer a reliable alternative to traditional steel wire or synthetic ropes, providing superior strength at a fraction of the weight. Their low weight not only makes handling significantly easier and safer for crew, but also reduces strain on deck equipment and enhances operation efficiency.

Ideal for both static and dynamic operations, Dyneema® Mooring lines and Towing ropes perform exceptionally well under demanding conditions. They are resistant to UV, saltwater, chemicals and abrasions - ensuring durability and long service life even in the harshest marine environments.

Whether securing a vessel alongside a berth or towing on offshore conditions, Dyneema® Mooring ropes and Towing ropes provide peace of mind where strength, resilience and safety are critical.

Features

- Strong as steel

- 10 times lighter than steel

- Low creep

- 3-4 % elongation

Applications

- Mooring

- Tugging

- Towing

Why choose Dynamica Towing & Mooring ropes?

Dynamica Mooring ropes offer a lightweight, strong, and reliable solution for securing vessels safely in port or offshore. They are the preferred choice for all types of vessels - from the biggest container carriers, bulk carriers, navy, tankers, LNG vessels, ferries, barges, tug boats, fishing vessels to luxury yachts and smaller boats. Recommended for split drums winch applications. Not recommended for use on H-bits, capstans cleats.

Dynamica Towing ropes are engineered to deliver outstanding performance during demanding towing and tugging operations. They are the preferred choice for ships, tugboats and other vessels engaged in both harbour and offshore towing tasks.

Dynamica Mooring & Towing ropes are made with HMPE/Dyneema® making them lighter, safer and just as strong as steel wire. Combined with their excellent abrasion and UV resistance, the ropes are ideal for a wide range of mooring and towing operations in wet and harsh maritime environments.

By choosing Dynamica Mooring & Towing ropes you gain:

Safe worksites

Low weight

Easy handling

Clean deck

Very high strength-to-weight ratio

Excellent fatigue life

Floats in water (depending on construction)

Less crew and heavy equipment for handling required

Resistant to most chemicals

No rust, long lifetime in the maritime environment

No need for grease/lubrication

High tension and bending fatigue resistance

Towing and Mooring rope construction

Dynamica Mooring & Towing ropes are manufactured with HMPE/Dyneema® in a 12-strand braided construction. Besides this, your ropes can be constructed in many different ways e.g. with a braided or woven cover made either of heavy duty polyester or Dyneema®. Both covers can get a final treatment with a Double Shield Coationg (DSC) which prevents abrasion, penetration of sand/mud particles and UV.

If used on high seas or with strong winds, it is recommended by OCIMF that the rope is fitted with nylon, polyester or mixed rope stretchers in order to absorb the shock loads.

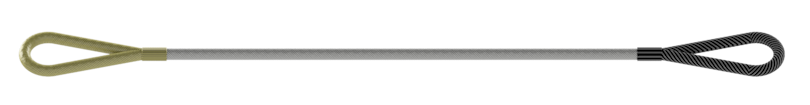

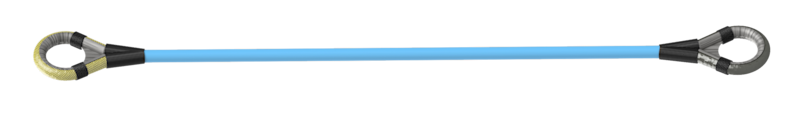

Pennant

Our standard construction is a pennant with eyes with or without braided cover.

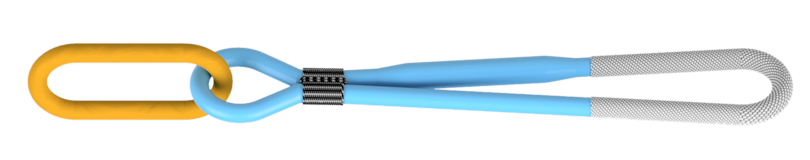

Thimble & masterlinks

Apart from the standard construction, Dynamica Mooring & Towing ropes can also be manufactured with customised solutions such as thimbles and masterlinks.

Elongation of Dynamica Mooring & Towing ropes

Dynamica Mooring & Towing ropes have a low elongation of only 3-4 %, which is similar to steel wire. For towing operations, this ensures more even tows. Thanks to their stiff construction, the ropes are also more comfortable and safer for the crew to handle.

Although we heat-stretch the Towing and Mooring ropes during production, you will experience elongation during initial use due to constructional elongation. However, after a few operations, the rope will become more length stable than their steel wire counterparts.

In case of breakage, the ropes' low mass and elongation results in the energy being distributed along the ropes’ entire length in a linear fashion. This results in a low and controlled recoil - unlike steel wire, which is known for lashing out and endangering people as well as equipment.

Do's & don'ts

To ensure maximum strength and safety, it's important to handle your rope correctly during spooling. Avoid rotating the rope, as this can disturb its internal construction and reduce its strength - potentially leading to premature failure during use.

When the rope is not in use, always store it in a dry, covered area, away from direct sunlight and high temperatures. UV rays can gradually weaken the rope fibres, so proper storage helps preserve the rope's performance and extend its service life.

To further protect your rope from UV-degration and harsh weather, we recommend applying a high-quality, weather-resistant coating. This extra layer of protection is especially important for ropes used in marine and offshore environments, where exposure to sun, salt and moisture is constant.

Taking these simple precautions will help maintain the integrity, strength, and reliability of your rope - keeping both your crew and operations safe.

Braided and woven covers & jackets

How to protect Dynamica Towing & Mooring ropes

To extend the lifespan of Dynamica Towing & Mooring ropes, we recommend using a protective cover made of braided or woven HMPE/Dyneema® or polyester.

The covers can be applied as follows

In the soft eyes

In the soft eyes and over the splice

In the soft eyes, over the splice in an agreed distance towards the middle of the rope

On the entire length

We always recommend covering the eyes and working ends, as these often are in contact with uncontrolled areas of service vessels or port facilities - areas where the crew has limited or no control.

Braided polyester cover

The braided polyester cover protects the rope against abrasion. It makes the rope non-floating, which is an advantage for some operations. On request, the cover can be treated with DSC.

Woven Dyneema® covers

Woven Dyneema covers offer exceptional abrasion resistance, making it ideal for use in the harshest and most demanding environments. It is used along the entire length of slings, ropes, tethers, and winch ropes, including bearing points and eyes, with a white cover that ensures maximum durability and protection for heavy-duty operations.

Dynamica PRO cover

Dynamica PRO is a braided Dyneema® cover which provides additional protection of the main rope. On request, the cover can be treated with DSC.

What to look for while inspecting Dynamica Mooring & Towing ropes?

Regular inspections ensure a long service life and keep the total cost of ownership down.

Inspect the mooring and towing rope before every operation looking for the following signs:

Rope construction damage

Cover damage

Spooling damage

Splice or eye damage

Abrasion

Inconsistent diameter

Explore our reliable rope solutions for the marine industry

Dynamica Ropes offers a wide selection of high-performance products built to meet the demanding needs of the marine industry. Whether for mooring, towing, or lifting, our ropes are designed with safety and security in mind. Ready for tough conditions and trusted worldwide, our products help to ensure smooth operations at sea. Explore our range of Mooring rope and Towing rope and select the rope solution that meets your requirements.

FAQ about Dyneema® Mooring rope & Towing rope

Dyneema® is a high-performance fibre made from ultra-high-molecular-weight polyethylene (UHMWPE). It is renowned for its exceptional strength-to-weight ratio alongside outstanding resistance to abrasion, chemicals and moisture. These qualities make Dyneema® ideal for Towing and Mooring ropes, where strength, durability and safety are essential. Its lightweight properties also improve handling and help reduce the risk of injury during rope operations.

Dyneema® ropes provide equal or even greater strength than steel wire ropes while being considerably lighter. Weight for weight, Dyneema® can be up to ten times stronger than steel. This allows for the same or improved performance using ropes that are significantly easier and safer to handle and that cause less wear on equipment.

Yes. Dyneema® ropes are specifically engineered to withstand harsh environments. They offer excellent resistance to ultraviolet (UV) exposure, maintaining strength even after prolonged sun exposure. They are also highly resistant to chemicals such as saltwater, oils and fuels, and they possess superior abrasion resistance, making them suitable for demanding mooring and towing operations.

Dyneema® ropes combine the benefits of both steel and synthetic materials. Compared to traditional synthetic ropes, Dyneema® offers greater strength and durability, while being much lighter than steel wire. Key advantages include:

High breaking strength at a lower weight

Excellent resistance to UV, chemicals and moisture

Minimal elongation under load

Improved safety and ease of handling

Buoyant – they float on water, aiding visibility and retrieval

These features make Dyneema® an optimal choice for marine applications requiring strength, reliability and ease of use.

Dyneema® is exceptionally lightweight—up to 85% lighter than steel wire ropes of equivalent strength, and significantly lighter than polyester or nylon alternatives. This substantial weight reduction enhances fuel efficiency, speeds up deployment and retrieval, and reduces physical strain and handling risks.

Yes. Dyneema® has a specific gravity of 0.97, which means it floats on water. This is a valuable feature in marine environments, as floating ropes are easier to locate, manage and retrieve—reducing the risk of snagging or fouling propellers and equipment.

The lifespan of Dyneema® ropes depends on the specific application and environmental conditions, but they typically last longer than ropes made from traditional materials. Their resistance to UV light, saltwater and abrasion ensures they retain their strength and flexibility over time. While the initial investment is higher, Dyneema® ropes often deliver greater value in the long term due to their durability and low maintenance requirements.