- Dynamica Ropes

- Products

- Tethers

Dynamica Offshore Tethers

Subsea/Deepsea fibre & rope Tethers

Technical information

| Load bearing material | HMPE/Dyneema® |

| Capacity | > 3000+ t of MBL |

| Length | Up to 100 m |

| Length tolerance | +/- 0.5 % or less according to customer specifications |

| Construction (fibre) | Endless loop |

| Construction (rope) | Single or multicore |

| Mud & sand filter | Particle barrier |

| Cover | HMPE/Dyneema®, Dual Cordura, HI-Vis Cordura |

| Visibility | Longitudinal reflective line |

| Certification | DNV, BV or other on request |

Need a datasheet?Go to solution request and fill in your details | |

Features

- Superior tension fatigue properties

- Precise length

- Low creep

- Extremely low length tolerances

Applications

- HD & HB tethering

- MWA tethering

- Riser tethering

- Permanent mooring

Why choose Dynamica Tethers?

Dynamica Tethers are reliable synthetic subsea mooring systems that secure risers, umbilicals and Mid-Water Arches connected to production systems, ensuring smooth flow of oil to processing facilities.

Dynamica Tethers are designed and manufactured for specific operations and according to customer specifications. Always engineered to withstand subsea conditions.

From single HMPE/Dyneema® filament to finished Tether, we have a conscious manufacturing process ensuring service life of up to 30 years.

Dynamica Tethers can be manufactured as either fibre or rope Tether depending on the required strength and length.

Technical support when designing your offshore tethering system

We design the complicated tethering systems using the latest CAD technology, where the Tether design and entire process are explained and a thorough product review is made in close cooperation with the customer.

All synthetic Tethers are manufactured to customer requirements and specifications ensuring the most suitable systems and cost effective solution for the application.

The most important focus is not to compromise on the Tether integrity. We always highlight the prevention of wear and tear and having the TAC (Tether Connection Points) as one of the very important review points determining the final design.

Our many years experience with designing synthetic solutions made with HMPE/Dyneema® enables us to engineer Tethers which are fit for the application.

Tether construction

Dynamica Tethers are custom-made and manufactured with HMPE/Dyneema® with quality and safety in focus.

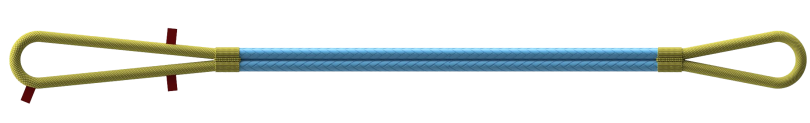

Rope Tethers

Dynamica rope Tethers can be manufactured as single or multicore. For certain applications rope Tethers are offered as a parallel laid construction with a number of sub-ropes.

Dynamica rope Tethers are made of 12 strand or multistrand ropes manufactured with HMPE/Dyneema® fibres. Rope Tethers are an option if your operation requires an extremely long length e.g. MWA Tethers or MWA back-up Tethers.

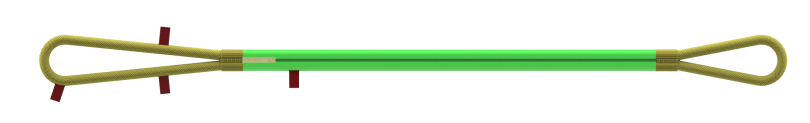

Fibre Tethers

Dynamica fibre Tethers are manufactured as endless loop.

The load bearing capacity of the Dynamica MWA Tethers has been verified by series of break tests. The basic yarn is purchased with material certificate and test data for each batch. The fabrication process is standardised and high quality machines are used for fabrication of the Tethers.

Terminations

Each termination, seized or spliced eye is controlled, securing the points of attachment from Tether to clamp or anchor.

Load bearing core

Dynamica Tethers are manufactured with HMPE/Dyneema® which is also called ultra-high molecular weight polyethylene (UMWPE), used for manufacturing several types of ropes, slings and Tethers.

Dynamica Tethers are the preferred choice for the subsea installation due to the minimal creep during up to 30 years of service.

How to cover & protect Dynamica Tethers?

Dynamica Tethers can have numerous layers of cover and protection, preventing any possible damage which can occur during either the installation or the long lifetime of the Tether.

Rope Tether protective covers

The multicore rope Tethers are often protected by an additional heavy duty braided jacket made with HMPE/Dyneema®.

Apart from that, Dynamica Tethers have numerous layers of woven covers adding protection which prevents any possible damage that can occur during either the installation or the long lifetime of the Tether.

Braided Dynamica PRO cover

The machine braided Dynamica PRO cover is a heavy duty braided jacked used for rope Tethers. The tight construction and hard braid, of this type of cover, secures the load bearing fibres from damage.

Woven Dyneema® protections

Woven Dyneema® covers are the most abrasion resistant of all covers making them an ideal choice for operations in the most harsh and risky environments.

Fibre Tether protective covers

Fibre Tethers are equipped with multiple layers of flexible laminated and PU-coated jackets eliminating any chance of particle ingress into the load-bearing core.

The design of HD Tethers and MWA Tethers has been chosen in order to achieve the best possible long-term performance under dynamic subsea load conditions.

The design of the Tether and the construction of the cover is always done in close cooperation with the customer. Dynamica Tethers are offered with several layers of jackets and additional heavy duty Dyneema® cover on the anchor points.

Reflective cover marker

Dynamica Tethers are fitted with longitudinal reflective markers on the entire length, enabling a high degree of visibility for the ROV operator during installation, eliminating any unwanted twists.

Mud & sand filter

Dynamica Tethers can be manufactured with sand- and mud filter which creates a barrier between the load bearing core and the multiple layers of cover.

The filter is an active barrier to particles and allows free flooding of the tether while protecting the load bearing core.

What is the weight of Dynamica Tethers?

Dynamica Tethers are as strong as steel but up to 10 times lighter, resulting in the following advantages:

Weight savings

Reduced installation time & costs

Higher fatigue resistance

ROV friendly, easy installation and change for divers and ROVs

Interested in a specific Tether? Request the information through the solution request!

What are Dynamica Tethers' fatigue properties?

Dynamica Tethers have significantly better fatigue properties than their steel counterparts. The fatigue life of Dynamica Tethers are calculated based on the fatigue data, required lifetime and construction of the Tether itself.

Synthetic materials like polyester, aramid and polyethylene outperform steel when it comes to fatigue based on the past 20 years of fatigue testing of synthetic Tethers and ropes.

Quality assurance of Dynamica Tethers

In order to ensure the highest quality of HD Tethers, the entire production and manufacturing process is digitally monitored.

Our selection of sub suppliers and monitoring of raw materials are done in accordance to the ISO 9001:2015 Quality Standard.

When purchasing a Dynamica Tether, you recieve a full document package.

What to look for while inspecting Dynamica Tethers?

Tethers have to be inspected visually by ROVs on a regular basis as part of the total subsea system inspection programme.

Each tether is delivered with a separate Installation, Operation & Maintenance Manual.

For more information about inspection, contact us!