- Dynamica Ropes

- Cases

- SPM hawsers made with dyneema® - a robust solution for offshore monsoons

Single Point Mooring hawsers made with dyneema®

- A robust solution for offshore monsoons

During the monsoon season, offshore production platforms face significant challenges. High winds generate large waves, creating intense water currents that stress mooring systems. These forces can cause severe wear and tear, leading to potential failures of critical components like SPM mooring hawsers, anchors, and lines.

Breakages in Single Point Mooring Systems (SPM) during these turbulent conditions can result in catastrophic consequences, including equipment damage, production shutdowns, or even environmental hazards.

Monsoons: A serious threat to offshore moorings

Monsoons cause dramatic storm surges and towering swells, significantly increasing wave height. These conditions destabilize offshore platforms, buoys, and anchored vessels, posing risks of collisions, capsizing, and severe damage. Moreover, turbulence caused by monsoon winds mixes different layers of water, leading to unexpected stress on mooring lines, as currents move in varying directions and speeds.

In one recent case, an offshore production rig experienced a breakage of an SPM hawser during the monsoon season, putting the entire operation at risk. The production was forced to shut down, which led to costly delays.

Dynamica Ropes’ rapid response with high-strength grommets

Faced with this urgent challenge, the customer needed a reliable solution to resume production as quickly as possible.

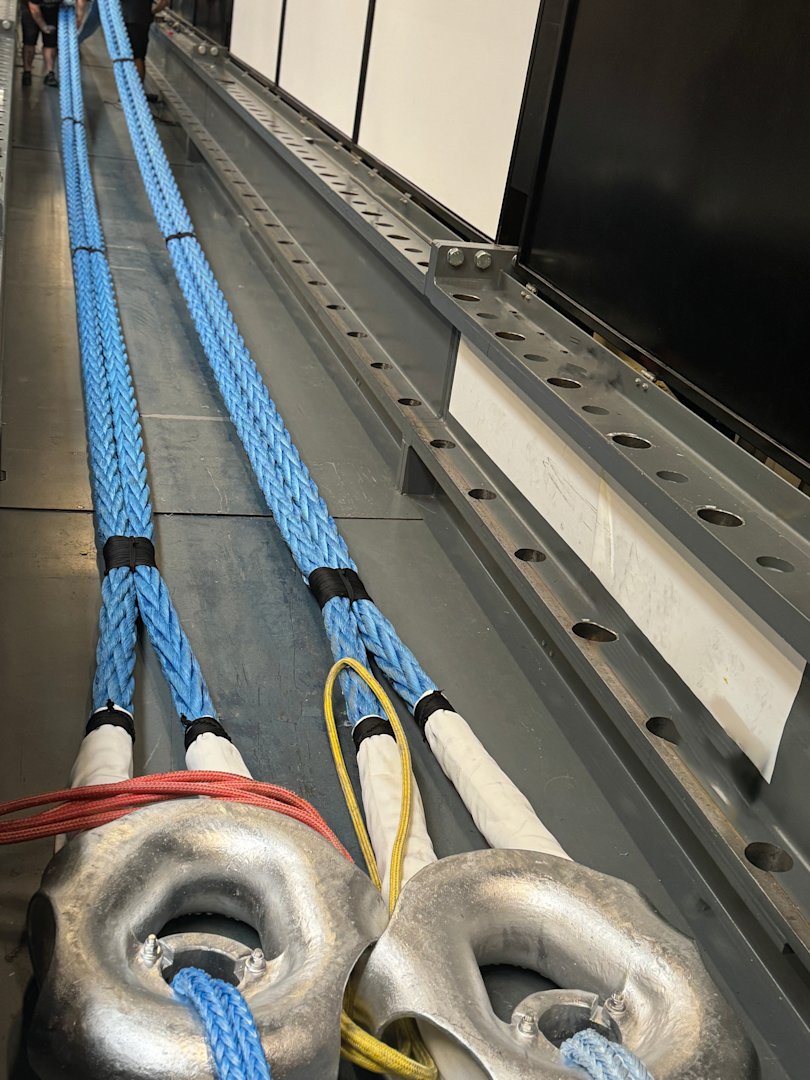

Dynamica Ropes provided an emergency replacement for the broken SPM mooring hawser in the form of two high-strength grommets made with 88 mm Dyneema® SK78 rope.

These grommets, each with a length of 70 meters and seized thimbles at both ends, had a Minimum Breaking Load (MBL) of 1,000 tons matching the necessary hawser behaviour.

They were tested and proof-loaded in our in-house testbed before departure.

Thanks to Dynamica Ropes’ quick response, the custom grommets were produced and delivered by air freight in just a few days.

The customer was able to resume production without further losses, demonstrating the importance of fast, reliable solutions in critical offshore applications.

What is a Single Point Mooring (SPM) System?

A Single Point Mooring System is a floating buoy that serves as a mooring point for offshore vessels, particularly tankers. These buoys are connected to the seabed using anchor chains or catenary anchor leg mooring systems. The SPM buoy allows for the transfer of liquid or gas cargo from the vessel to the shore or vice versa via flexible hoses and a product transfer system.

The SPM system is a critical component in offshore tanker operations as it enables vessels to load or unload cargo in deep waters without having to dock at a terminal.

The critical role of Single Point Mooring systems

In offshore operations, Single Point Mooring (SPM) hawsers play an essential role in maintaining the stability and security of vessels during product transfer in challenging marine environments. These hawsers are responsible for withstanding the enormous forces generated by waves, wind, and currents, particularly in open-sea conditions where vessels are constantly exposed to environmental stresses.

The design and strength of a Single Point Mooring hawser are critical in preventing mooring failures, which can lead to severe operational disruptions or even catastrophic events such as tanker collisions or oil spills and environmental disasters. By absorbing and distributing the dynamic loads placed on the mooring system, Single Point Mooring hawsers ensure that the vessel remains securely moored to the SPM buoy, even in extreme conditions like storms or monsoons.

In addition to handling constant movement and shifting mooring loads, SPM hawsers provide a crucial buffer that helps mitigate the risk of sudden breakage or overloading. Their capacity to flex and stretch under pressure allows them to manage the strain placed on mooring lines and anchor systems, offering an added layer of protection to the overall mooring arrangement.

Ultimately, the reliability of an SPM system depends heavily on the quality and performance of its hawser arrangement. These components are often the first line of defence against the intense mechanical stresses involved in offshore mooring operations, making them indispensable in ensuring the safety and efficiency of offshore tanker operations.

Why choosing the right SPM hawser matters

Investing in high-quality SPM hawsers is crucial for ensuring the long-term safety and efficiency of offshore mooring operations. The right hawser not only provides the strength and flexibility needed to handle the extreme forces encountered in open seas but also minimizes the risk of costly failures, such as breakages or equipment damage, that could disrupt production and jeopardize the environment.

Durable materials, like Dyneema®, offer significant advantages, as emergency back-up and replacements in SPM mooring systems. These hawsers are designed to withstand harsh marine conditions, including heavy loads, constant movement, and severe weather. Their exceptional resistance to abrasion and fatigue helps reduce wear and tear, extending the lifespan of the mooring system and lowering costs.

By choosing high-performance Single Point Mooring Systems, operators can enhance the reliability of their mooring systems, ensuring the safety of vessels, crews, and surrounding ecosystems. The investment in quality hawsers not only protects offshore operations from unexpected disruptions but also contributes to long-term operational success.

High-strength grommets made with 88 mm dyneema® SK78 rope

Mooring grommet with MBL 1000t

Customized to 70m length with heavy duty thimbles

12 strand rope made from Dyneema fibers