- Dynamica Ropes

- Cases

- Retired after 3997 jobs

Dynamica Tow lines offer excellent performance

After 3997 jobs, Svitzer retired their Dynamica Tow ropes. The tow rope was end-to-end turned after the 2000 jobs.

“Masters are very pleased with the performance of the tow line”

Andy, Master at Svitzer

With a full history of the line’s service, number of towage jobs and also active escorts etc. the rope was retired after 3997 jobs and the tug operator order the replacement.

According to the mutual agreement was returned to us for product testing and evaluation since it is of interest for the tug operators to find out the residual strength and condition of the line.

Visual inspection

The visual inspection showed that the rope and cover was in very good shape, much better than could be expected - it was clear that is had been taken good care of.

The cover on the eye is in good state. The eye 'neck' and cover is compressed due to the cowhitch. The compression forced the cover to open up down the eye.

In some places, the tow rope was twisted around its axse meaning the rope was deformed and had a 'square' shape. This most likely happened as a result of burring on the winch. The compression of rope, can influence the breaking strength of the rope.

Break test

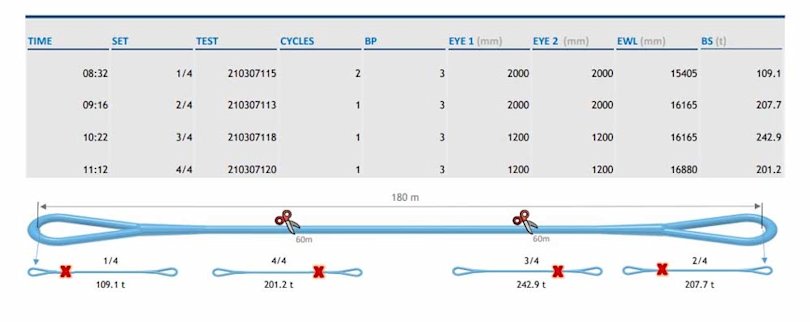

We performed 4 different break tests:

- Outer eye (cow hitch eye) + new eye

- Inner eye

- Tests approx. 60 m down the rope from each eye end (2 new splices)

In the test results below the “X” marks where the rope parted.

“We are very pleased with the performance of our Dynamica Tow lines. They have been in service since installation and have completed 3997 jobs.”

Master at Svitzer

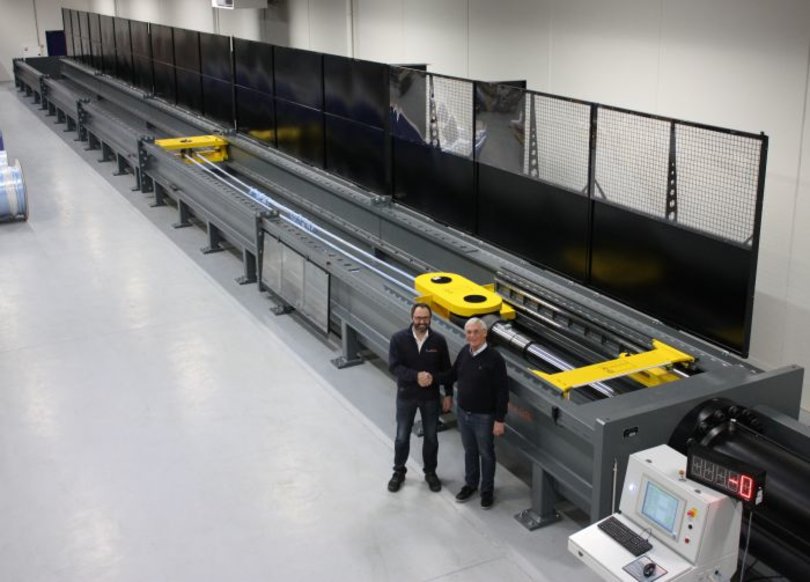

The extra 1997 jobs with no issues were possible due to our manufacturing process; the tow lines are manufactured with genuine HMPE/Dyneema® and pre-stretched in the heat stretching unit. Thereby, gaining strength when under repeated tension as the fibres are organised due to the heat and tension applied.

“The bespoken main line is additionally connected to a working pennant (20 m x 56 mm Dynamica jacketed line). These pennants are replaced every 2000 jobs (end for ended after 1000 jobs).”

Master at Svitzer

Dynamica Tow lines

Maximum strength

Minimal weight & recoil

Greater safety & effeciency