- Dynamica Ropes

- Cases

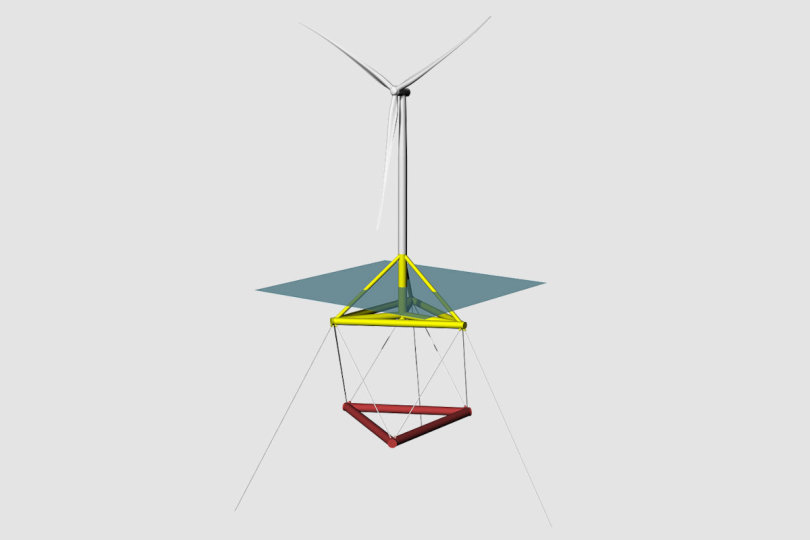

- Stiesdal TetraSpar replace steel with synthetic rope

Floating wind demonstrator replace steel with synthetic keel lines

The TetraSpar Demonstrators stability is provided by a keel deployed 50 m below the floater. This keel deployment is the main challenge for the offshore installation; the design left limited space available and by taking into account the functional requirements, recommendations were made to optimise the system design with minimal material use.

- this would not have be possible to achieve with traditional steel wire ropes.

The solution were Dynamica DM20 ropes made with Dyneema® as this type of rope is 7 times lighter than steel wire at the same strength. The huge Dynamica Keel Lines connects the top floater with the bottom ballast keel.

The ballast keel was elevated during the first part of the sea transfer to the place of destination, a towing route of 360 nautical miles. Once the vessel reached sufficient water depth, the last part of the journey from Skagen, Denmark to Stavanger in Norway was done with the ballast keel winched down.

Commissioned at a water depth of 200 m, the floating wind turbine is now installed at the test site of the Marine Energy Test Centre outside Stavanger in Norway. (Photo 'TetraSpar Demonstrator ApS')

“We have been very pleased to work with Stiesdal from the early beginning of the project. It has been a long-term process and we have been looking forward to the successful installation outside Stavanger”

Jørgen Sørensen, CEO at Dynamica Ropes

The strong understanding of the Dyneema® fibres, manufacturing process of fabrication and installation of keel lines, our R&D team, with the support of DSM, offered optimised rope design to be applied for future floating wind farms.

“Dynamica Ropes is committed to accelerate the development of the floating wind market through its recent investment in a huge braiding machine, which will be able to manufacture synthetic mooring ropes for offshore applications up to 2000 t MBL”

Kate Christensen, Sales Manager at Dynamica Ropes

Interested in learning more about the TetraSpar project ->

Dynamica Keel lines

7 times lighter than steel

Uptimised rope design

Mooring ropes up to 2000 t MBL